HQJC

*Please click the bottom of the page to see the video of the jaw replacement accuracy test!

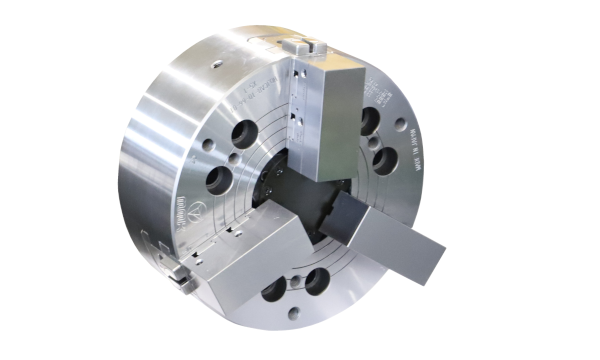

MMK's original pawl changing system is an evolution of QJC and ROBO-QJC.

MMK's original double slide is superior in rigidity and durability.

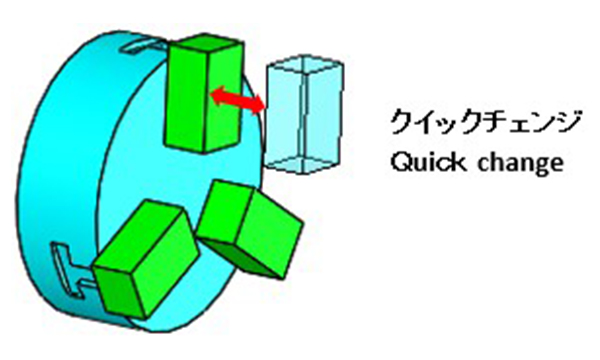

No need to adjust the serration, and quick jaw change is possible.

Jaw change repeatability ≦10μm

Top jaw replacement system prevents ingress of chips.

HQJC jaws have no bolt holes, making R-forming easy,

HQJC jaws have no bolt holes and have no edges, which prevents scratches on the workpiece and improves the accuracy of finish processing.

Both automatic and manual jaw changes are possible with the robot hand.

Automatic operation including changeover is possible when used with Smart Terrace AIO.

Method

| unit | HQJCA5-6-35B-02 | HQJCA6-8-46-01 | HQJCA8-10-66-02 | HQJCA8-12-67-01 | HQJCA11-15-103-01 | HQJCA15-18-165B-01 | |

|---|---|---|---|---|---|---|---|

| Nominal chuck diameter | (inches) | 6 | 8 | 10 | 12 | 15 | 18 |

| Allowable maximum rotation speed | min-1 | 4,600 | 4,100 | 3,700 | 2,700 | 1,800 | 1,500 |

| Jaw stroke | mm | φ4.7 | φ6.4 | φ8 | φ8 | φ9.5 | φ9.5 |

| Shifter stroke | mm | 15 | 20 | 25 | 25 | 30 | 30 |

| Workpiece diameter Max. | mm | φ151.2 | φ189 | φ228.6 | φ274.5 | φ342.9 | φ411.3 |

| Workpiece Diameter Min. | mm | φ42 | φ52 | φ59.6 | φ65 | φ101 | φ177 |

| Maximum gripping force | KN | 46.3 | 82.3 | 98.8 | 114.7 | 147 | 147 |

| Allowable cylinder thrust | KN | 17.2 | 28.1 | 32.1 | 42.9 | 51.9 | 51.9 |

| Mass | kg | 14 | 25 | 43 | 75 | 137 | 210 |

| Applicable cylinder | **** | **** | **** | **** | **** | **** |

Draw screws (F) are also available in sizes other than those shown in the table above. Please contact us for details.

HQJC chucks use reaction force to grip the workpiece or jaw forming ring to secure the jaws.

The jaw clamping is not complete in the empty gripping state when no gripping reaction force is generated.

Rotating the chuck at 100 r.p.m. or more is dangerous because the jaws may be scattered by centrifugal force.

Do not rotate at speeds higher than 100 r.p.m. in an empty grip condition.

Also, depending on the situation, install an interlock or similar device on the machine to which the jaws are to be attached.

Download Materials

| PDF (EXTERIOR VIEW) | DXF (EXTERIOR VIEW) | |

|---|---|---|

| HQJCA5-6-35B-01 | Download | Contact Us |

| HQJCA6-8-46-01 | Download | Contact Us |

| HQJCA8-10-66-01 | Download | Contact Us |

| HQJCA11-15-103-01 | Download | Contact Us |