Product

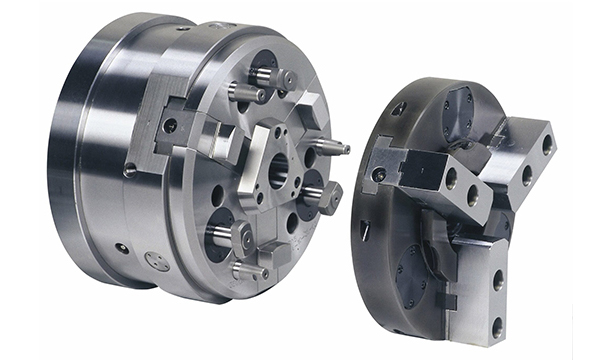

AJC

Closed center 3 jaw power operated chuck (auto jaw exchange chuck)

Automatic set up

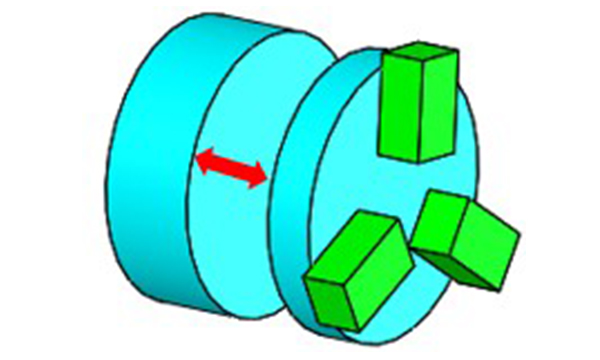

All jaws can be replaced simultaneously by simply replacing the replacement plate on which the jaws are mounted.

This chuck system is suitable for high-mix low-volume production and automated operation.

Suitable for irregularly shaped workpieces and workpieces requiring seating confirmation.

Use in combination with our RNW type cylinder.

Method

| unit | AJCA 6- 8- 17- 27 | AJCA 8- 10- 35- 19 | AJCA 8- 12- 46- 20 | AJCA 11- 15- 72- 05 | AJCA 11- 18- 72- 06 | |

|---|---|---|---|---|---|---|

| Nominal chuck diameter | (inches) | 8 | 10 | 12 | 15 | 18 |

| Allowable maximum rotation speed | min-1 | 3,600 | 3,500 | 2,500 | 1,250 | 900 |

| Jaw stroke | mm | Φ10.7 | Φ9 | Φ9 | Φ13.3 | Φ13.3 |

| Shifter stroke | mm | 20 | 20 | 20 | 30 | 30 |

| Workpiece diameter Max. | mm | Φ180 | Φ216 | Φ261 | Φ342.9 | Φ411.3 |

| Workpiece Diameter Min. | mm | Φ27.8 | Φ42.9 | Φ34 | Φ67 | Φ126 |

| Maximum gripping force | KN | 58.8 | 85.3 | 94.1 | 114.7 | 147 |

| Allowable cylinder thrust | KN | 31.9 | 37.2 | 41.2 | 47.5 | 60.8 |

| Weight of chuck body | kg | 32.2 | 55 | 100 | 181 | 230 |

| Replacement plate mass | kg | 7.8 | 17 | 27 | 52 | 75 |

| Mass | kg | 40 | 72 | 127 | 233 | 305 |

| Exchange plate clamp stroke | mm | 30 | 31 | 32 | 37 | 37 |

| Replacement plate clamping force | KN | 29.4 | 42.6 | 42.6 | 52.9 | 52.9 |

| Applicable cylinder | RNW 155- 20- 02 | RNW 155- 20- 02 | RNW 155- 20- 02 | RNW 195- 30- 01 | RNW 195- 30- 01 |

Short taper type (JIS B 6109) or straight fitting type can be selected according to the shape of the spindle end of the mounting machine.

Draw screw (F) sizes other than those shown in the table above can also be selected. Please contact us for details.

Draw screw (F) sizes other than those shown in the table above can also be selected. Please contact us for details.

Download Materials

| PDF (EXTERIOR VIEW) | DXF (EXTERIOR VIEW) | |

|---|---|---|

| AJCA 6- 8- 17- 27 | Download | Contact Us |

| AJCA 8- 10- 35- 19 | Download | Contact Us |

| AJCA 8- 12- 46- 20 | Download | Contact Us |

| AJCA 11- 15- 72- 05 | Download | Contact Us |

| AJCA 11- 18- 72- 06 | Download | Contact Us |