Jaw RFID Stocker Matching Detection

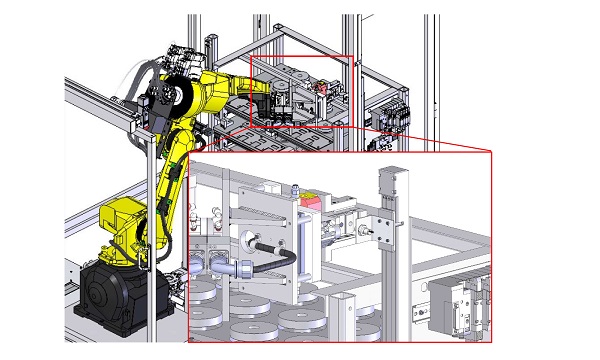

The IC chip is embedded in the partition plate on which the workpiece (material or finished product) is placed and in the jaws of the lathe chuck that grips the workpiece. The partition plate is set with the machining program NO. (O NO.) of the workpiece to be placed on the partition plate. The program NO. and jaw number are set in the jaws of the chuck. This ensures that the workpiece and jaws match, and the jaws are installed in the position corresponding to the jaw number.

Furthermore, the program NO. is transferred to the NC device, and the corresponding program is automatically called up. When the material on the dividing board runs out and the robot tries to grip the next workpiece, it automatically judges that the workpiece is finished because it becomes empty.

The operator only needs to place the material and the chuck jaw appropriate for the material on the dividing board and automatically apply the chuck jaw. Processing always starts from the top of the multi-stage stocker and returns to the top when the stocker runs out. Automatic scheduling is completed simply by setting the workpiece.