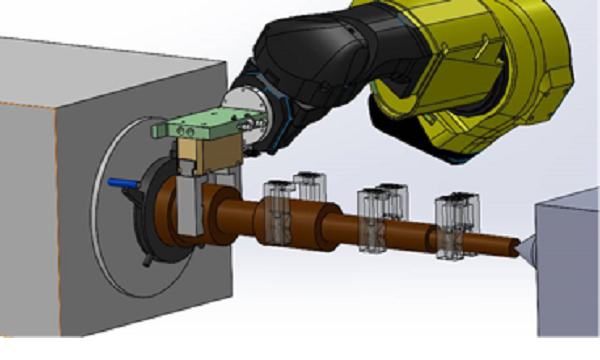

Robot hand size measuring device for cylindrical grinder

Measuring hand

The measuring position can be programmed at multiple points for each workpiece (various diameters can be measured within 15 mm of each other).

The strength of Matsumoto's machines is that they can handle data until it is entered into the NC device's OFFSET, and the ability to output measurement data to EXCEL is also available as an option.

Calibration function (zero compensation function) eliminates the need for a master workpiece. The jaw itself has a calibrating function, and the calibrating position and measuring position are as close as possible to each other, making it difficult to be affected by dimensional changes due to temperature changes.

Hand for both workpiece transfer and measurement

This hand transfers and measures workpieces with a single jaw.

The gripping force during transfer and measurement can be automatically switched.

Advantages of Multi-point Measurement

Conventional constant dimension devices are expensive, so they measure one point and compensate by estimating the diameter of other points from the measured value.

However, the estimated value sometimes did not match the estimated value due to heat generation caused by different machining conditions.

Multi-point measurement enables compensation based on directly measured values rather than estimation.